...IoT...

The term "

Internet of Things" is used to describe a system where the Internet is connected to the physical world via ubiquitous sensors

[1]. In an

article dated June 22, 2009 in the RFID Journal Kevin Ashton said -

Today computers—and, therefore, the Internet—are almost wholly dependent on human beings for information. Nearly all of the roughly 50 petabytes (a petabyte is 1,024 terabytes) of data available on the Internet were first captured and created by human beings—by typing, pressing a record button, taking a digital picture or scanning a bar code. Conventional diagrams of the Internet include servers and routers and so on, but they leave out the most numerous and important routers of all: people. The problem is, people have limited time, attention and accuracy—all of which means they are not very good at capturing data about things in the real world.

And that's a big deal. We're physical, and so is our environment. Our economy, society and survival aren't based on ideas or information—they're based on things. You can't eat bits, burn them to stay warm or put them in your gas tank. Ideas and information are important, but things matter much more. Yet today's information technology is so dependent on data originated by people that our computers know more about ideas than things.

We need to empower computers with their own means of gathering information, so they can see, hear and smell the world for themselves, in all its random glory. RFID and sensor technology enable computers to observe, identify and understand the world—without the limitations of human-entered data.

Gartner Inc. states that the Internet of Things will grow

to 26 billion units installed in 2020, representing an almost 30-fold

increase from 2009. Furthermore, Gartner said that IoT product and

service suppliers will generate incremental revenue exceeding $300

billion, mostly in services, in 2020. The market research firm further

states IoT will result in $1.9 trillion in global economic value-add

through sales into diverse end markets.Is IoT the latest hype ? Most of the opportunities predicted from IoT are nothing new. Everything

will be connected but most those items like cars, appliances, printers,

etc. have been talked about for more than a decade. The big

differentiator this time is advanced sensor technology, but how long

before these sensors become commodities? OK, so most of these devices

will be IPv6, but what's the big deal about what standards they use to

communicate? Most of the chatter about IoT seems to be evolutionary, not

revolutionary.

[2]

Data is all around us, data we cannot see - Dark Data. If harnessed properly this data can be quantified and utilized to make this planet a better place to live (jeezz...). Unless people make smart use of IoT it will just remain in the evolutionary stage. Everthing will just remain an Internet-of-Thermostats...

Allright, i am fed up gathering data visit this

link to read further.

That Temperature Thing...

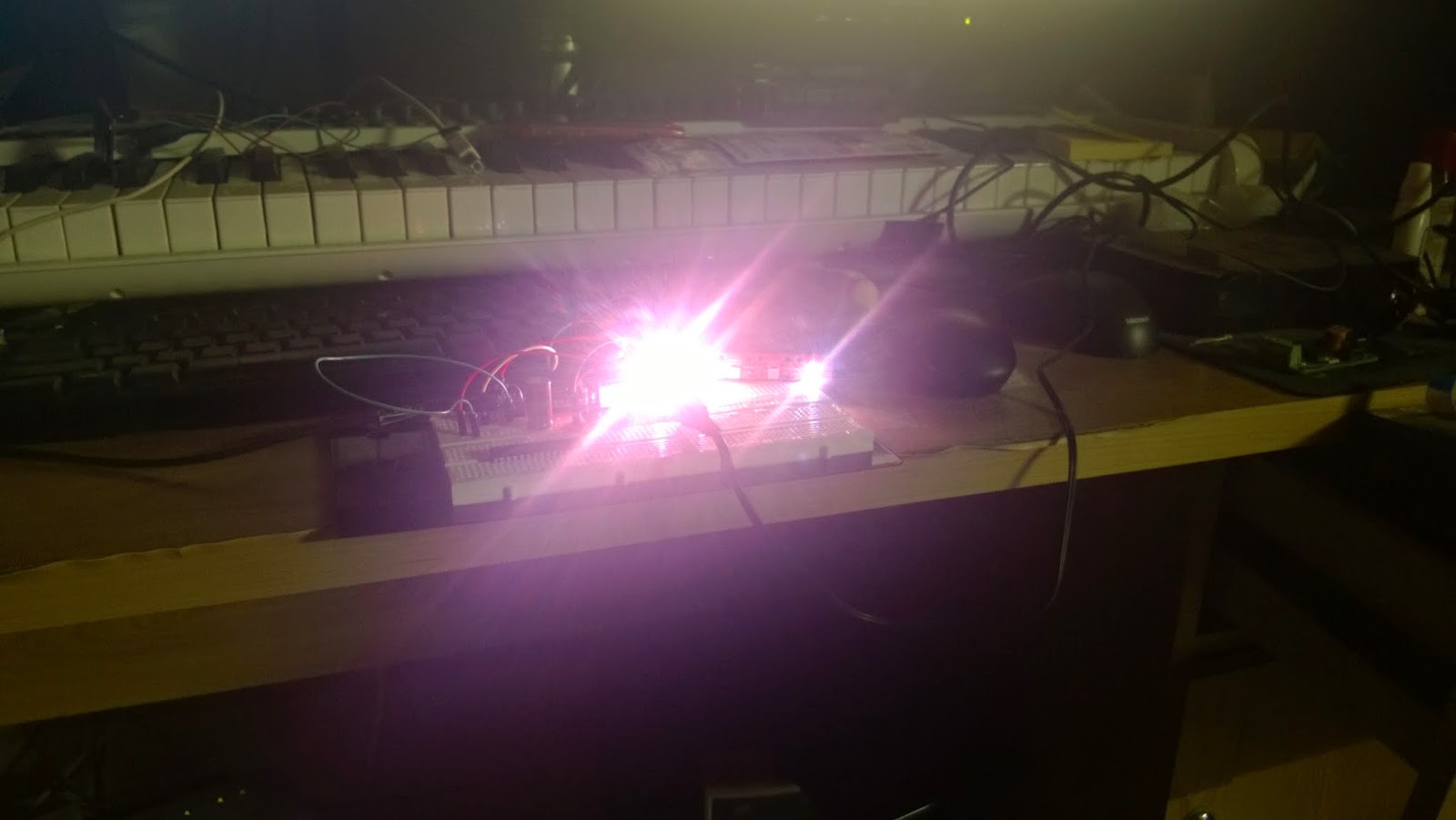

Now to the real content for which this post is meant for. In a nutshell - i've used the Sparkfun Weather shield connected to the Arduino to send the temperature, humidity and luminosity data of my room to a Xively server using a Adafruit CC3000 TI WiFi sheld. This is the stacked up assembly. The bottom board is an

Arduino Uno R3, in the center there is the

Adafruit WiFi shield and the

Sparkfun weather shield on top. Pretty neat arrangement eh ? Rapid prototyping at it's finest with such boards available...

The data is displayed on the Xively website. Surprisingly i have observed that the data transmission to the server is slow. It takes approximately 40 seconds after a connection has been established with the server to upload the JSON formatted data using the UNO R3. The entire code for the Arduino sketch is shown below and some screenshots from the Xively site. Most of the code has been adapted from Adafruit's learning site with minor modifications by me for the weather shield.

Does a demo like this come under the hood of IoT ? Well, right now, if i stop this project here, then No, it does not. The data is merely being displayed, it does not control any-thing or talks to any other thing to modify that thing's behavior. This just validates the platform on which future IoT applications aspire to run on...

The light levels started to increase from 05:53 hrs in the morning as seen in above graph.

The sunrise time as per local weather station data was indeed 05:53 A.M

It is pretty hot out here. Those spikes you see are me turning off the air cooling of my room. 37.99 degrees celcius was the maximum temperature hit inside my room...after which i turned on the air conditioning

If you are reading this post and have some information to share on the CC3000 as to why it takes so much time to push data to the website, leave a comment below. Thanks for reading through...

And

that's a big deal. We're physical, and so is our environment. Our

economy, society and survival aren't based on ideas or

information—they're based on things. You can't eat bits, burn them to

stay warm or put them in your gas tank. Ideas and information are

important, but things matter much more. Yet today's information

technology is so dependent on data originated by people that our

computers know more about ideas than things.

- See more at:

http://www.rfidjournal.com/articles/view?4986#sthash.uvAv1voe.dpuf

Today

computers—and, therefore, the Internet—are almost wholly dependent on

human beings for information. Nearly all of the roughly 50 petabytes (a

petabyte is 1,024 terabytes) of data available on the Internet were

first captured and created by human beings—by typing, pressing a record

button, taking a digital picture or scanning a

bar code.

Conventional diagrams of the Internet include servers and routers and

so on, but they leave out the most numerous and important routers of

all: people. The problem is, people have limited time, attention and

accuracy—all of which means they are not very good at capturing data

about things in the real world.

- See more at:

http://www.rfidjournal.com/articles/view?4986#sthash.uvAv1voe.dpuf

Today

computers—and, therefore, the Internet—are almost wholly dependent on

human beings for information. Nearly all of the roughly 50 petabytes (a

petabyte is 1,024 terabytes) of data available on the Internet were

first captured and created by human beings—by typing, pressing a record

button, taking a digital picture or scanning a

bar code.

Conventional diagrams of the Internet include servers and routers and

so on, but they leave out the most numerous and important routers of

all: people. The problem is, people have limited time, attention and

accuracy—all of which means they are not very good at capturing data

about things in the real world.

- See more at:

http://www.rfidjournal.com/articles/view?4986#sthash.uvAv1voe.dpuf

Today

computers—and, therefore, the Internet—are almost wholly dependent on

human beings for information. Nearly all of the roughly 50 petabytes (a

petabyte is 1,024 terabytes) of data available on the Internet were

first captured and created by human beings—by typing, pressing a record

button, taking a digital picture or scanning a

bar code.

Conventional diagrams of the Internet include servers and routers and

so on, but they leave out the most numerous and important routers of

all: people. The problem is, people have limited time, attention and

accuracy—all of which means they are not very good at capturing data

about things in the real world.

- See more at:

http://www.rfidjournal.com/articles/view?4986#sthash.uvAv1voe.dpuf

Today

computers—and, therefore, the Internet—are almost wholly dependent on

human beings for information. Nearly all of the roughly 50 petabytes (a

petabyte is 1,024 terabytes) of data available on the Internet were

first captured and created by human beings—by typing, pressing a record

button, taking a digital picture or scanning a

bar code.

Conventional diagrams of the Internet include servers and routers and

so on, but they leave out the most numerous and important routers of

all: people. The problem is, people have limited time, attention and

accuracy—all of which means they are not very good at capturing data

about things in the real world.

- See more at:

http://www.rfidjournal.com/articles/view?4986#sthash.uvAv1voe.dpuf